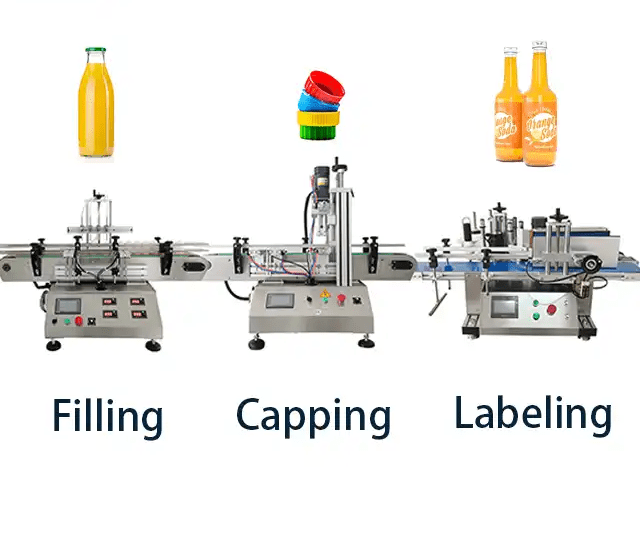

Description

| Description:- | |

| Products Name : | Automatic Bottle Liquid Filling Capping Machine |

| Brand Name ; | Nicko |

| Modal No, : | EDWS NK202365157 |

| Product name: | Automatic Bottle Liquid Filling Capping Machine |

| Machinery Capacity | 4000BPH, 2000BPH |

| Packaging Material | Plastic, Glass |

| Filling Material | Beer, Milk, Water, Oil, Juice |

| Filling Accuracy | ±1% |

| Applicable Industries | Manufacturing Plant, Food & Beverage Factory, Home Use, Construction works |

| Application | Food, Beverage, Commodity, Chemical, Machinery & Hardware |

| Packaging Type | Bottles |

| Automatic Grade | Automatic |

| Driven Type | Electric |

| Weight | 140 KG |

| MOQ: | 1pcs |

| Core Components | Motor, Pressure vessel, Pump, PLC, Bearing, Engine |

| Type | Filling Machine |

| Voltage | 110v/220v |

| Dimension(L*W*H) | 130*90*100CM |

| Function | Bottle Filling Capping |

| Usage | liquid Filling Packaging |

| Material | Stainless Steel |

| Operation | Automatic Operation |

| Filling speed | 30-60 Bottles/min |

| Packaging & delivery ; | |

| Packing | Wooden Case |

| Fixed In Standard export carton | |

| Machine surface protection, plastic fastening | |

| Manufacturer logo printed on the outside of package | |

| Lead Time : | 10 to 15 days |

| Quantity(pieces) | 1-2 3-10 >10 |

| Lead time (days) | 15 25 To Be Negotiated |

Performance analysis

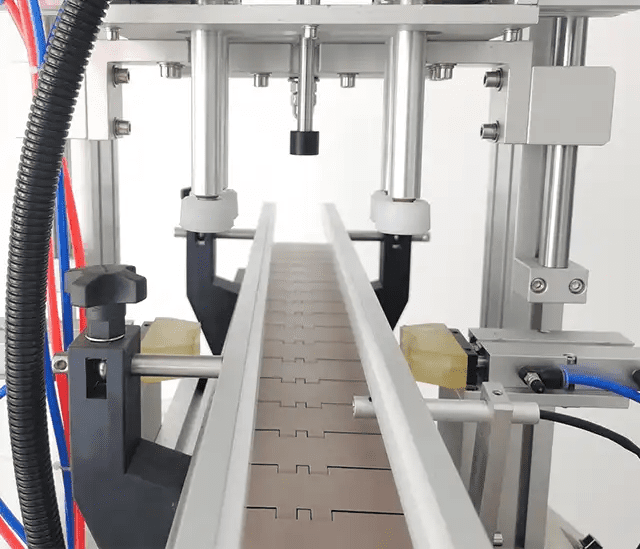

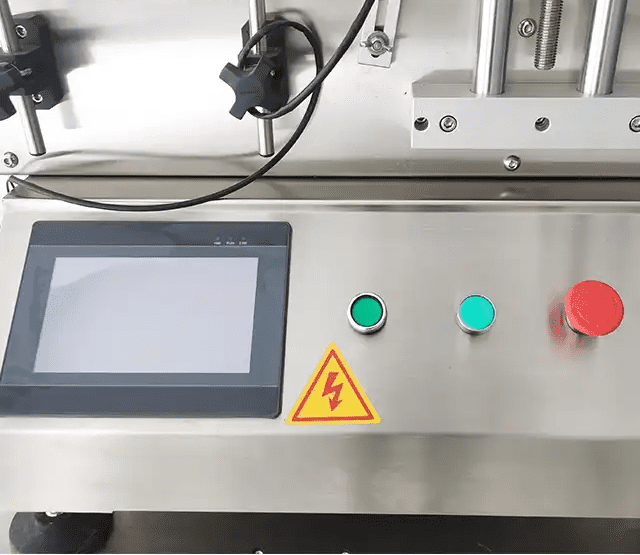

Features (1).PLC combined with LCD touch screen panel,the setting and operation is clear and easily. (2).The equipment is complied with GMP requirements and made of SUS304 stainless steel and high-class aluminium alloy. (3).The machine has many functions such as measuring, filling, counting. (4).The filling speed,volume can be adjusted. (5). The machine can be used in production line with conveyor belt. (6). Photoelectric sensor,mechatronic filling adjusting system,material level control feeding system.

| Filling volume | 4×(5-500ml) (Can be customized according to your requirements) |

| Filling speed | 1600b/h for 500ml |

| Filling precision | ±0.5% |

| Filling head | 2/4/(Can be customized according to your requirements) |

| Filling type | Liquid |

| Air pressure | 0.6-0.8Mpa |

| Weight | 130kg |

| Voltage | 220V/110V; 50hz/60hz |

| Size | 1300*800*800mm |

Working Principle * Core principle: the sensor detects the product passing return signal to the control labeling system, PLC signal after processing, at the appropriate time delivering the label attached to the product in the set position, the product flows through the cover label, labels, coated solid , a label attached to the action is completed. * Procedure: put the product (which can be accessed pipeline) -> product delivery (automatically) -> Products correct (automatically) -> Product Inspection (automatically) -> labeling (automatically) -> Cover standard (automatically ) -> label products have been collected. Features 1.The whole machine adopts a mature PLC control system to make the whole machine run stably and at high speed. 2. General-purpose bottle separation device, no need for replacement of parts for any diameter bottle shape,quick adjustment and positioning Note:(optional and adjustable rotating wheel included) to achieve the perfect universal bottle labeling machine. 3.Operating system with touch screen control, easy operation, practical and highefficiency .Adopting labeling speed, conveying speed and dividing speed can realizestepless speed regulation and adjust according to need. Application * Applicable to round objects and bottom labels for food, cosmetic,chemical and other industries. * Suitable for round bottle labeling of various sizes. brush buoy body, the label is more firmly attached。 * Optional connection line in the rear section, optionally equipped with a receiving turntable for easy collection, sorting and packaging of finished products

| item | Value |

| Model | EDWS NK202365156 |

| Voltage | AC220V 50Hz AC110V 60Hz |

| Power | 400w |

| Labeling speed | 25-50 pcs/min (related to material and label size) |

| Labeling accuracy | ± 1.0mm (material and label size excluded) |

| Label roll inner diameter | ≥φ75mm |

| Max label roll out diameter | ≤φ250mm |

| Suitable bottle | Φ40mm-100mm(Can be customized according to your requirements) |

| Biggest label size | W*L 150*180mm(Can be customized according to your requirements) |

| Packing size | 130*80*80cm |

| Packing weight | 130kg |

Application

This machine is suitable for the filling of liquid, such as juice,water,beer, alcohol, oil. The whole machine with exquisite design,remove unnecessary complexity and heavy machinery.Maintenance and repair no need professionals,as long as the simple adjustment.Four filling heads with high accuracy It is also suitable for assembly line.

Reviews

There are no reviews yet.